Project details

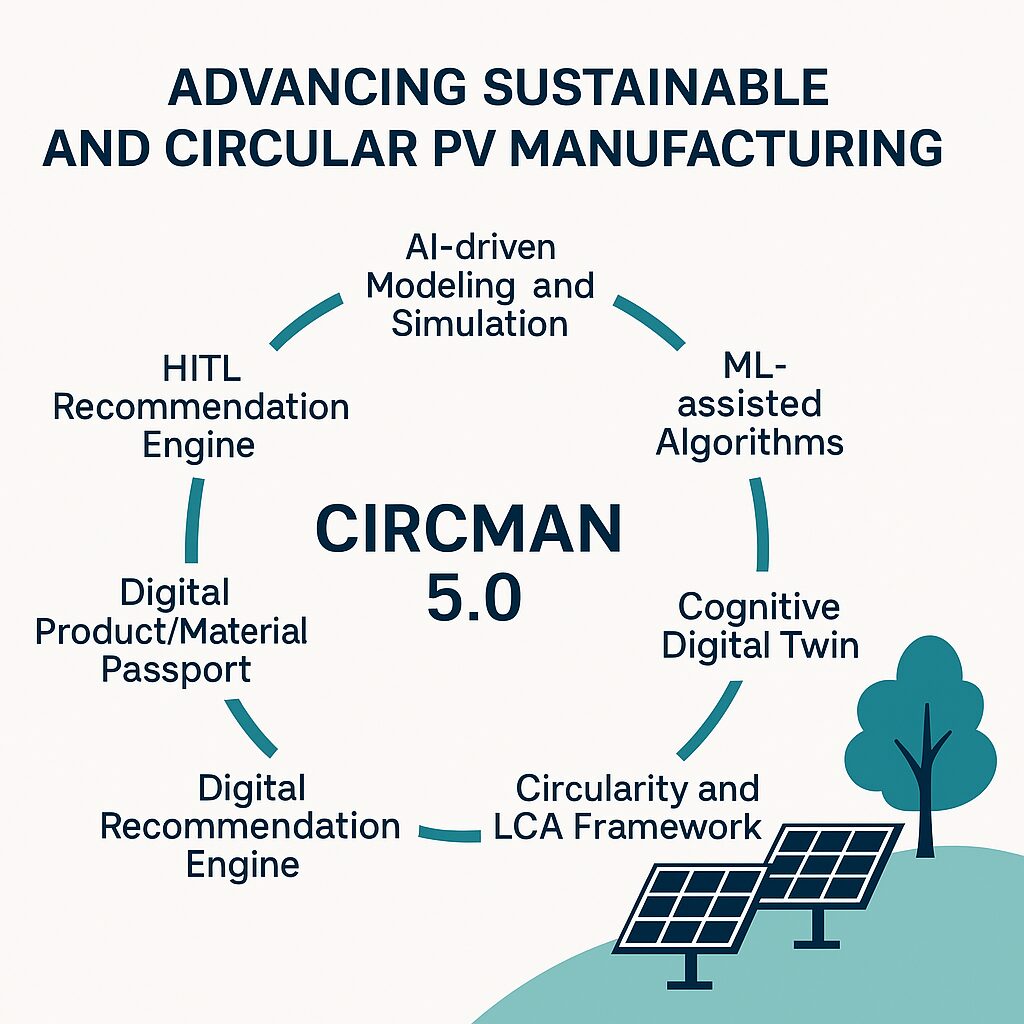

CIRCMAN 5.0 is making substantial strides in the field of sustainable and circular photovoltaic (PV) product manufacturing. This innovative ecosystem of advanced technologies is designed to enhance the modeling and simulation pipeline, ultimately assessing the environmental sustainability of PV products.

The project introduces a groundbreaking Human-Centered AI-aided Digital Framework for the PV manufacturing industry, empowering stakeholders to:

CIRCMAN 5.0’s impact is measured through specific KPIs focused on reducing waste, improving transparency, validating materials, conserving energy, and enhancing productivity.

For more information see the project website: